|

|

|

|

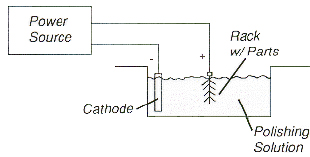

Electropolishing |

||||||

|

|

|||||

Parts are placed in a concentrated acid solution as the anode (positive side) of an electric circuit. An oxygen layer forms in the low areas of the surface, leaving the peaks exposed. Because the peaks receive greater current density than the valleys, more metal ions are pulled from the peaks than the valleys. |

||||||

|

||||||

Our tanks are 10 feet long, three feet wide and 4 and a half feet deep and hold 900 gallons. The solution that Allbright uses is ideally suited for 200, 300 and 400 series stainless. The average operating temperature of this 100% acid solution is 150° F. Process times vary depending on the part and the quantity. Average processing time is from fifteen minutes to thirty minutes. |

||||||

|

|

||||||

| 2 |

© Copyright 2002 - 2004 by Allbright Electropolishing, Inc. All rights reserved.